The E-Coat Process

E-coat is what the automotive industry uses to coat metal parts under the hood and under the body of vehicles to resist rust and corrosion.

E-coat is a durable protective coating in the industry and is applied to many components on a vehicle to protect them from chips and peeling and to provide rust protection for many years.

E-coat is known by many names such as Electrodeposition, Electropheretic, Electro-deposit and Elpo Dip — just to name a few! Under the “Certifications” tab you can learn more about the paint specifications we meet or exceed. Our intent is to be able to pass any known automotive paint specification.

Our 12-stage in-line cleaning and zinc phosphate pre-treatment prepares the parts for the painting process and is very robust so the paint has good adhesion and salt spray resistance. We use black epoxy paint in our e-coat process.

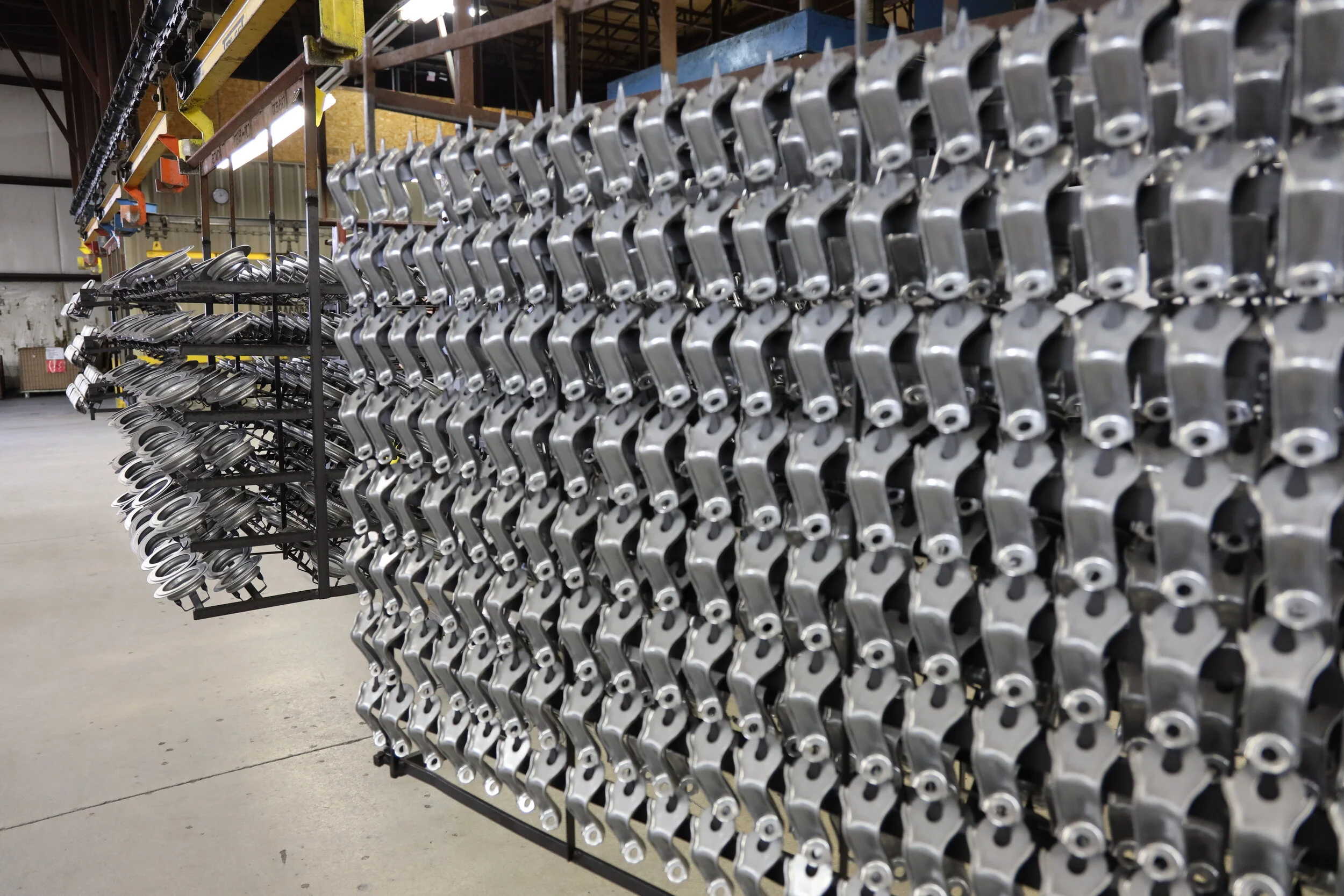

E-coat is a liquid paint applied electrically in a dip tank, submerging the part for complete coverage as opposed to spraying the e-coat on the part and ensures 100% coverage on hard-to-access surfaces.

After the metal components are submerged through the cleaning, rinse and phosphate, they are then submerged into the E-Coat tanks where the electrically bonded paint is applied before advancing to the rinse tank to remove the excess paint, which gives it a smooth, run-free surface. Unlike plating, the paint is then cured in an oven that completes the cross-linking of the epoxy resin, giving a tough salt-resistant finish.

Check out our Process Flow document here.

An Advanced Coating technology that has:

No Lead

No Chrome

Low HAP’s (Hazardous Air Pollutants)

Very low VOC’s (Volatile Organic Compounds or Solvents)

Consistent with film build which is somewhat controllable

Excellent Adhesion

Outstanding corrosion resistance

Very efficient material utilization

Excellent coverage of complex configurations with recessed areas

An automated process with high production capabilities

Excellent appearance

Excellent priming qualities for top coats

Capability to coat a wide range of conductive surfaces